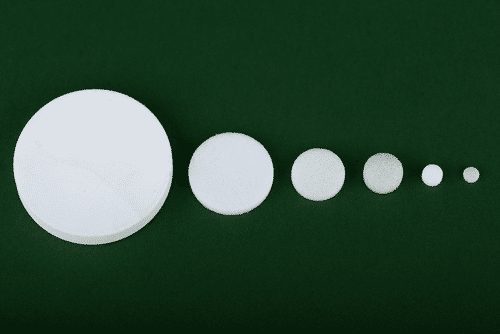

Sintered Filter

Price 12 INR/ Number

Sintered Filter Specification

- Heat Resistance

- Yes

- Color Pattern

- Uniform

- Surface Finish

- Smooth

- Tensile Strength

- 18 MPa

- Leak Protection

- Yes

- Density

- 0.95 Gram per cubic centimeter(g/cm3)

- Plastic Type

- PE (Polyethylene)

- UV Resistant

- No

- Melting Point

- 110C

- Type

- Sintered Filter

- Material

- Polyethylene (PE)

- Shaping Mode

- Moulding

- Length

- 60 mm

- Weight

- 8 g

- Hardness

- Shore D 60-65

- Plastic Molding Type

- Injection Moulding

- Color

- White

- Size

- Customizable

- Connection Type

- Press Fit / Snap Fit

- Porosity

- 40-80 micron

- Filtration Accuracy

- Up to 40 micron

- Pressure Resistance

- Up to 4 bar

- Chemical Resistance

- Excellent against acids and alkalis

- Shape

- Cylindrical

- Reusable

- Yes

- Sterilization

- Autoclavable

- Flow Rate

- 12-40 L/h

- Application

- Air and water filtration, gas filtration, powder separation

- Operating Temperature Range

- -20°C to +80°C

About Sintered Filter

Professionally trained staff, world-class infrastructure and international standard raw materials enable us to design and manufacture the best quality Porous Plastic Filter Cylinders, Candles & Pipes. With experience of over 45 years of manufacturing filtration elements, we are well-known as the leading manufacturers and suppliers of filter cylinders, filter candles and filter pipes. We use only the highest quality polypropylene, polyethylene, polystyrene and ultra-high density high molecular weight polymers to ensure that our porous plastic products are the best in the market.

Our superior product quality and our wide range of Porous Plastic Filter Cylinders, Candles & Pipes has made us synonymous with porous plastic filtration in India.

Our filter elements are used in a variety of applications, including Air Filtration, Water Filtration, Pneumatic Silencing & Muffling, Diffusion & Emission, Filtration for Biomedical Processes, Battery Filtration, Self-Sealing Filters and Wicking. Our Porous Plastic Filter Cylinders, Candles & Pipes are used by the Private, as well as the Government sector; primarily nuclear power plants. Our filtration products are used in a variety of industries, including Manufacturing, Industrial, Retail, Biomedical, Biotechnology, Pharmaceutical, Healthcare, Hospitality and Automotive.

The porous nature of our products prevents the passage of unwanted particles, thus filtering any liquid or gas that passes through it. We can customize the micron rating and pore size of our filter cylinders, filter candles and filter pipes in order to prevent passage of particulates irrespective of size, as per requirements, with minimal back pressure.

We have perfected the art of manufacturing porous plastic filters and ensure zero media migration from any of our products. Our Porous Plastic Filter Cylinders, Candles & Pipes are strategically designed to function at complete capacity even under high pressure, high temperature or when subjected to high air flow. In addition, we can provide our filter elements with self or external threading, and with exterior plastic grill (for additional strength), if required.

Please Note: Characteristic of the products can be customized as per requirements (such as dimensions, shape, porosity, micron rating, etc.)

Superior Filtration Performance

Engineered for demanding applications, this sintered filter provides precise filtration up to 40 microns. Its controlled porosity and smooth surface finish ensure consistent flow rates and optimal separation efficiency, making it a reliable choice for both industrial and laboratory settings.

Robust Chemical and Pressure Resistance

Made from durable PE, the filter exhibits excellent resistance to acids, alkalis, and pressures up to 4 bar. Its molded design ensures uniformity, while leak protection and a stable surface finish enhance performance under rigorous conditions.

User-Centric Features and Applications

With versatile connection types-press fit and snap fit-the filter simplifies installation and maintenance. Autoclavable and reusable, it suits air and water filtration, gas filtration, and powder separation across varied industries in India. Customization options are available to meet specific user requirements.

FAQ's of Sintered Filter:

Q: How is the sintered filter installed and removed in filtration systems?

A: The filter is designed with a press fit or snap fit connection type, enabling easy and secure installation and removal without the need for specialized tools, making maintenance straightforward.Q: What benefits does the 40-80 micron porosity offer for air, water, and gas filtration?

A: This porosity range efficiently removes particulate matter up to 40 microns, ensuring reliable filtration performance in air and water purification, gas filtration, and powder separation processes.Q: When should the sintered filter be sterilized and how is it cleaned for reuse?

A: Sterilize the sintered filter using an autoclave before reuse in applications requiring stringent hygiene. Routine cleaning involves flushing with compatible solvents, as the filter is resistant to acids and alkalis.Q: Where can this filter be utilized in industrial applications?

A: It is suitable for use in air and water filtration units, gas filtration systems, and powder separation equipment across different industrial sectors that require reliable filtration with chemical resistance and leak protection.Q: What is the manufacturing process used for this sintered PE filter and why?

A: The filter is manufactured through injection moulding and sintering processes, which provide precise control over porosity, ensure uniform color and a smooth surface finish, and guarantee mechanical strength and leak protection.Q: What are the main advantages of choosing a reusable, autoclavable filter made from PE?

A: Reusable and autoclavable filters reduce operational costs and environmental impact. Polyethylene's chemical resistance to acids and alkalis ensures longevity, and its durability supports repeated cycles of filtration and cleaning.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Porous Plastic Category

Porous Plastic

Price 5 INR / Number

Minimum Order Quantity : 10

Melting Point : 120C 130C

Shaping Mode : Molding

Color : White

UV Resistant : Yes

Filter Discs

Price 8 INR / Number

Minimum Order Quantity : 10

Melting Point : Above 1400C

Shaping Mode : Round

Color : Silver Grey

UV Resistant : Yes

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry