Filter Discs

Price 8 INR/ Number

Filter Discs Specification

- Melting Point

- Above 1400C

- Tensile Strength

- High

- Heat Resistance

- Yes

- Density

- Gram per cubic centimeter(g/cm3)

- Surface Finish

- Fine Mesh

- Leak Protection

- Yes

- UV Resistant

- Yes

- Color Pattern

- Plain

- Type

- Filter Disc

- Material

- Stainless Steel

- Shaping Mode

- Round

- Length

- Customizable

- Weight

- Lightweight

- Hardness

- Rigid

- Color

- Silver Grey

- Size

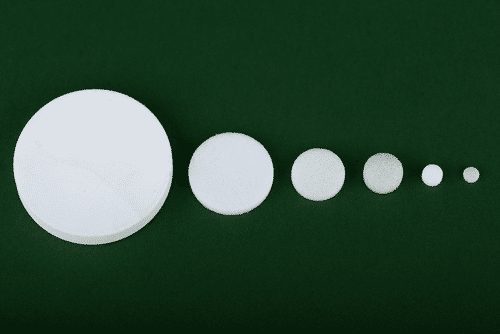

- Various Sizes (25 mm to 100 mm)

- Shape Options

- Round, Oval, Other on Request

- Customization

- Custom Sizes, Shapes, and Mesh Available

- Application

- Oil, Gas, Liquid, and Air Filtration

- Filtration Precision

- 5 to 500 Micron

- Packing

- In Polybags or Carton Boxes

- Installation

- Easy to Install

- Edge Type

- Plain/With Rim

- Corrosion Resistance

- Excellent

- Mesh Type

- Single/Multiple Layer Mesh

About Filter Discs

As a pioneer and the market leader in manufacturing of porous plastic products in India, we have been manufacturing Porous Plastic Filter Discs for more than 45 years. Our cutting-edge technology and state-of-the-art infrastructure enable us to manufacture high quality Porous Plastic Discs in bulk, at competitive prices.

Depending on the application, we can provide Porous Plastic Discs made from polystyrene, polypropylene, polyethylene or UHDHM polymers. We only use grade-A raw material, to ensure that our Filter Discs are of the highest quality. We have a highly developed manufacturing system, which enables us to make filter discs ranging from 1 mm to 1,000 mm in diameter and 2 mm to 50 mm in thickness.

Our Porous Plastic Filter Discs are used in a variety of applications, including Air Filtration, Water Filtration, Diffusion & Emission, Biomedical Filtration and Battery Filtration. In the recent past, we have developed and successfully provided a large quantum of filter discs, of varying specifications, to be used in the biomedical field; in Pipettes, Dialyzers for Dialysis, HPLC Filters and Medical Droppers.

Since, all of our competitors and many of our clients are internationally located, we continually conduct extensive research & development exercises to improve the quality and efficiency of our Porous Plastic Discs and similar filter elements, in order to surpass international quality standards. This has propelled us as the leaders in India in manufacturing porous plastic products and lets us successfully compete with the international players.

Our specialty lies in customizing our products as per the customers requirements.

Please Note: Characteristic of the products can be customized as per requirements (such as dimensions, shape, porosity, micron rating, etc.)

High Performance & Versatile Filtration

Designed for demanding environments, these filter discs provide fine filtration with precision ratings from 5 to 500 microns. They are perfect for applications in oil refineries, chemical plants, gas processing units, and HVAC systems. The combination of superior corrosion resistance, high heat tolerance, and robust durability ensures reliable performance and long-lasting service.

Customization & Easy Installation

Choose from various sizes, mesh configurations, and edge types to match your operational needs. Whether you need round, oval, or uniquely shaped filter discs, customization is readily available. These lightweight, rigid discs can be installed effortlessly, minimizing downtime during replacements or maintenance.

FAQ's of Filter Discs:

Q: How are stainless steel filter discs installed in filtration systems?

A: Our stainless steel filter discs are designed for straightforward installation. Depending on your system, they can be placed between flanges or housed within filter cartridges. The lightweight and rigid design ensures a secure fit, and customization options allow for precise matching with your existing setup.Q: What are the primary benefits of using these filter discs in industrial applications?

A: These filter discs offer excellent corrosion and heat resistance, high tensile strength, and effective filtration in a variety of environments. Their durability ensures a longer service life, reducing replacement frequency, while the customizable mesh and shape options enhance adaptation to diverse operational needs.Q: When should I choose a customized mesh type or size for my filtration needs?

A: Custom mesh types or sizes are recommended when you have unique filtration requirements, such as specific fluid properties or system dimensions. Our customization allows you to select the ideal filament diameter, mesh layering, and shape for optimal performance in your particular application.Q: Where can these filter discs be utilized effectively?

A: These filter discs are highly effective in oil, gas, liquid, and air filtration across industries such as petrochemical, pharmaceutical, food processing, and water treatment. Their resistance to corrosion and high temperatures makes them suitable for both harsh and sensitive environments.Q: What is the process for ordering filter discs with special specifications?

A: To order custom filter discs, simply provide your required dimensions, mesh type, shape, and quantity. Contact our sales team with these specifications, and we will assist you in designing and manufacturing discs tailored to your application's demands.Q: How does the high heat resistance benefit performance in critical applications?

A: The ability to withstand temperatures up to 800C ensures that these filter discs maintain structural integrity and filtration effectiveness even under extreme thermal conditions, which is vital for applications in high-temperature processing or environments exposed to thermal fluctuations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Porous Plastic Category

Sintered Filter

Price 12 INR / Number

Minimum Order Quantity : 10

Melting Point : 110C

Tensile Strength : 18 MPa

Material : Polyethylene (PE)

Size : Customizable

Porous Plastic

Price 5 INR / Number

Minimum Order Quantity : 10

Melting Point : 120C 130C

Tensile Strength : 10 20 MPa

Material : Polyethylene (PE)

Size : Custom Size Available

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry